Unlocking Precision: The Collaboration of FK Instrument Co and Camtech Engineering Services with Mastercam Multiaxis

In the intricate world of precision engineering, the synergy between innovative technology and collaborative partnerships often yields groundbreaking results. Such is the case with FK Instrument Co (FKI) and Camtech Engineering Services, whose collaboration, fueled by the power of Mastercam, has propelled them to the forefront of Mastercam multiaxis machining excellence.

A recent feature on SME.org sheds light on the dynamic partnership between FKI and Camtech, showcasing how they leverage Mastercam’s advanced capabilities to push the boundaries of precision manufacturing. At the heart of their success lies a shared commitment to innovation and a relentless pursuit of excellence.

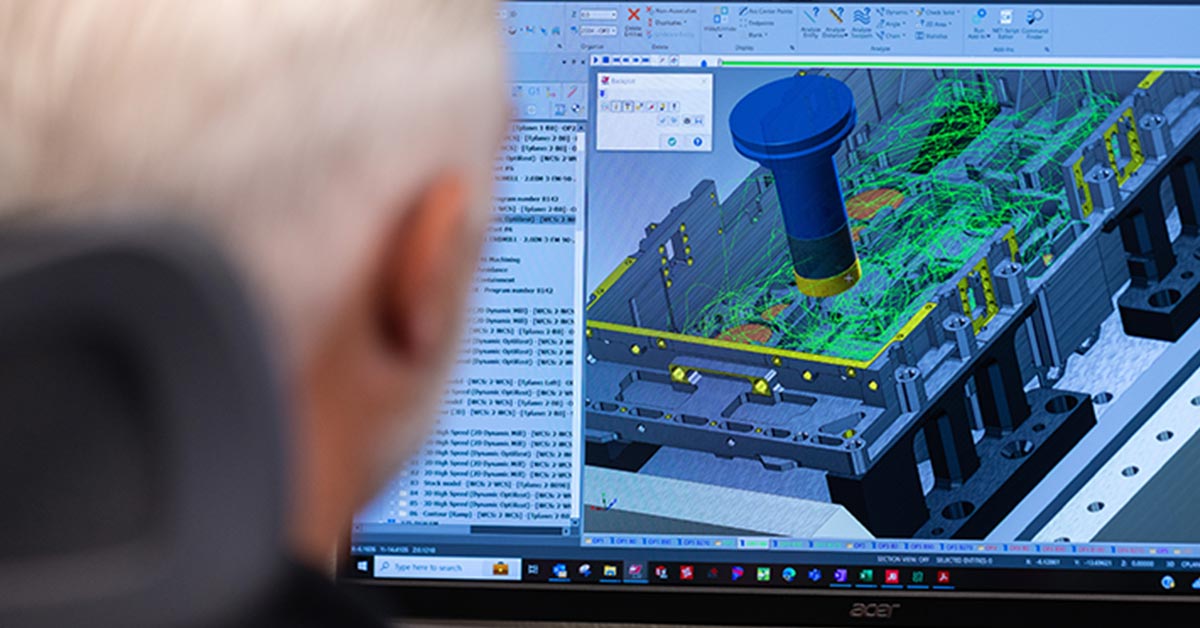

The article delves into the intricacies of multiaxis machining, a domain where FKI and Camtech excel. With Mastercam as their trusted ally, they have harnessed the full potential of multiaxis machining, unlocking new possibilities in design complexity and manufacturing efficiency.

One of the key highlights of their collaboration is the seamless integration of Mastercam’s powerful toolpath generation algorithms into their workflow. These algorithms optimize tool movements with unparalleled precision, minimizing machining time and maximizing productivity. As a result, FKI and Camtech are able to deliver exceptional quality and consistency in their machined components, setting new standards for excellence in the industry.

Moreover, the article explores how Mastercam’s advanced control systems and sensor integration have further enhanced FKI and Camtech’s capabilities. Real-time monitoring and adjustment of machining parameters ensure optimal performance and process stability, allowing them to tackle even the most challenging machining tasks with confidence.

But perhaps the most compelling aspect of their collaboration is the way in which Mastercam enables them to seamlessly merge additive manufacturing with Mastercam multiaxis machining. By leveraging the strengths of both technologies, FKI and Camtech can produce complex components with intricate internal structures, opening up new avenues for innovation in product design and functionality.

The impact of their collaboration extends far beyond the confines of traditional manufacturing sectors. From aerospace to medical devices, FKI and Camtech’s mastery of multiaxis machining, powered by Mastercam, is reshaping the landscape of precision engineering, driving innovation and pushing the boundaries of what is possible.

In conclusion, the partnership between FK Instrument Co and Camtech Engineering Services exemplifies the transformative potential of collaborative innovation. With Mastercam as their guiding force, they continue to redefine the standards of excellence in precision manufacturing, inspiring others to reach for new heights in the pursuit of engineering perfection.

To delve deeper into the remarkable journey of FK Instrument Co and Camtech Engineering Services with Mastercam multiaxis, read the full article here: Pushing the Boundaries of Multiaxis Machining